Monitoring-

Report Feed 2014

PARAMETERS UNDER THE MICROSCOPE

Feed monitoring is a tool for self-assessment at each individual business location. Testing feed for compliance with maxi-

mum levels, intervention level values and guidance values enables us to draw conclusions regarding in-house quality as-

surance. At the same time, the result supplied by a sample shows directly whether a specific feed lot or batch can be

marketed without reservation.

Heavy metals

Heavy metals head the hit list of most frequently analysed parameters. As these metals are typical environmental toxins,

nearly all feed products and raw materials have to be tested for possible traces. The focus is on arsenic, lead, cadmium

and mercury. Some products also need to be tested for nickel.

FEED “HOTSPOTS”

Aflatoxin finds in corn under control

With feeds given to dairy cattle, a QS gui-

dance value of 1 µg/kg of Aflatoxin B1 applies

in addition to the maximum legal concentra-

tion. If values are above this level, QM-Milch

e.V. must be notified in addition to QS head

office. If utilisation in dairy cattle businesses

cannot be excluded, the supplier must, as a

precaution, notify the customer that the QS

guidance value has been exceeded by issuing

a warning such as “Product not suitable as

feed for dairy cattle”.

■

Every business in the QS scheme that produces or trades in feed

undertakes to participate in feed monitoring. Year-on-year compa-

risons show that the number of tests is increasing. One reason is

that more and more companies are joining the QS scheme. The

fact that the highest number of tests were conducted on feed ma-

terial is due to the interconnected control system: the participants

monitor both their raw materials and the end products. Based on

this procedure, therefore, every stage monitors the previous stage

as well as its own production process and output. The compound

feed producers are the most frequent “testers”: 45.6 % of all sam-

ples were taken by compound feed producers, 26.7 % by feed ma-

terial producers, 4.4 % by traders and 0.2 % by additive producers.

23.1 % of all samples were taken on farms/agricultural businesses,

with cattle farming businesses accounting for 49.7 % of these

latter samples, pig farmers for 46.5 % and poultry businesses for

3.8 %.

■

PECULIARITY:

AFLATOXIN B1 AND QM MILK

HAND IN HAND: A SUPPLY

CHAIN CONTINUES TO

GROW TOGETHER

2011

2012

2013

Feed

sector

Number of participants

In total

Feed material

producer

Compound feed

producer

Trader

3,133

3,350

3,573

1,227

1,160

1,254

1,245

1,333

1,233

661

863

1,080

12,610

13,860

16,333

7,372

9,048

9,212 57 91 124

11 47 50

2011

2012

2013

Type

of feed

Number of samples

Feed material/

Raw Material

Compound

feed

Premixtures

Additives

Number of samples in type of feed in %:

Feed materials are mostly analyzed

Sampling frequencies sorted by industry in % :

Compound feed producer take most of the samples

Compound feed producer

Feed material producer

Farmer

Trader

Premix and

4.4

23.1

0.2

45.6

26.7

Additive producer

49,312

108,357

13,416

4,509

38,186

78,883

10,904

3,351

120,000

Parameters

Number of analysis

100,000

80,000

60,000

40,000

20,000

Heavy metals

Salmonella

Dioxins and dl PCB

Animal components

ndl PCB

Antibiotically active substances

PAH

Mycotoxines

19,167

27,358

29,137

27,559

27,759

26,478

26,561

3,221

As

DON

Pb

Cd

Hg

ZEA

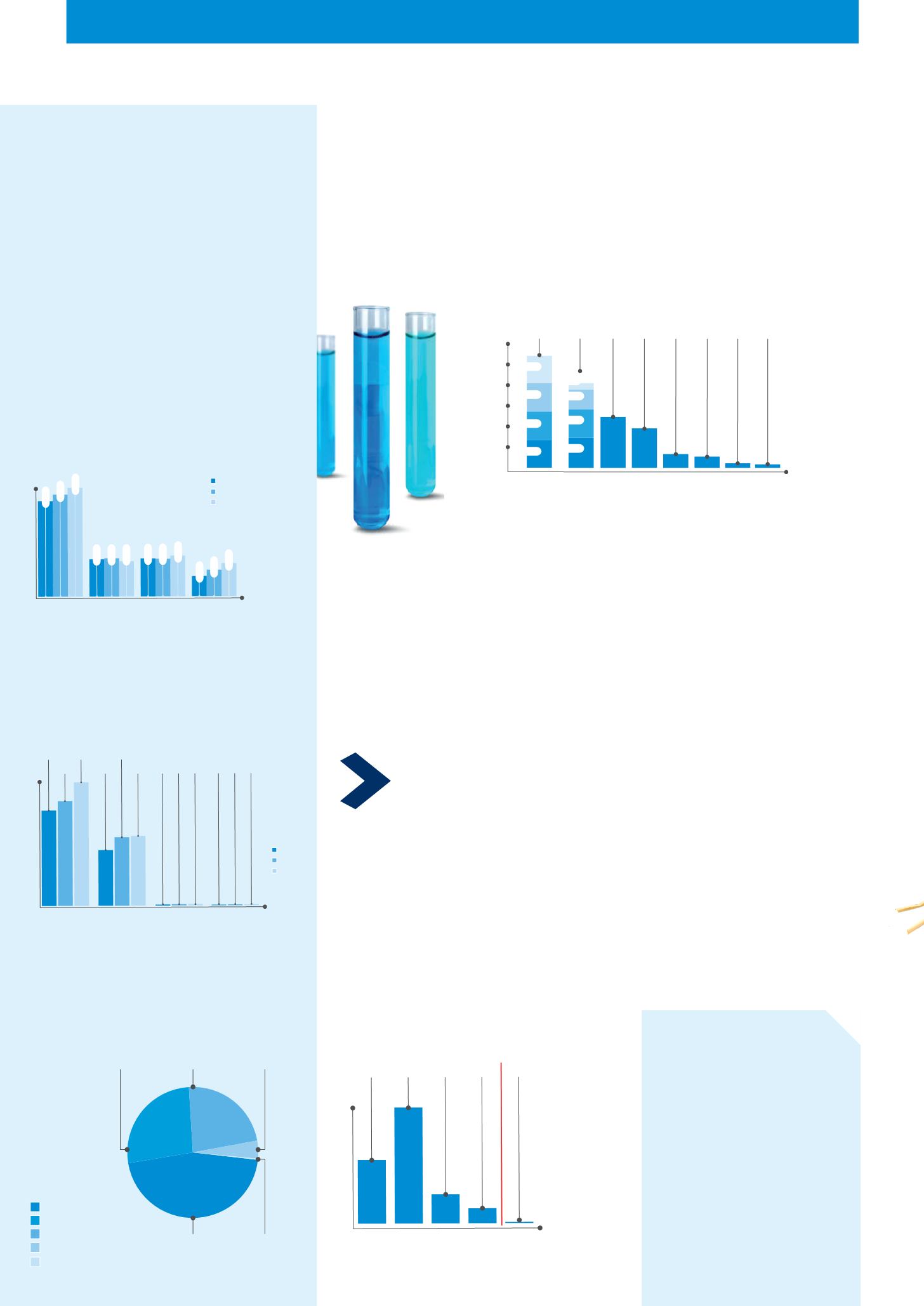

Afla

OTA

496

124

64

5

272

0-1

µg/kg

>1-5

µg/kg

>5-10

µg/kg

>10-20

µg/kg

>20

µg/kg

HG

20 µg/kg

Measured

value

Number analysis

Number of analysis per parameter: Heavy metals are number one

Growing participant numbers feed monitoring

QS AD-HOC MONITORINGPLAN FOR CORN TAKING HOLD

With the alarming finds of Aflatoxin B1 at the beginning of 2013, which found its way into the market in maize consignments

from Serbia, it became clear very quickly that Aflatoxin B1 contamination was also to be expected to an increasing extent

in corn from other regions since the harvest in 2012. QS reacted immediately. An Ad-hoc monitoringplan for corn from

certain countries of origin was prescribed as early as May 2013. Ever since, compound feed producers, feed material pro-

ducers and dealers have had to have samples taken of every batch of corn and processed corn products from the affected

countries during the receiving inspection of raw materials – 100 % monitoring. The inspection results show that the sector

has responded, either by changing suppliers or no longer purchasing products from certain regions. The maximum con-

centration in a batch was only exceeded in five instances, four times in corn and once in corn gluten meal. The scheme

participants had to take immediate action here, however, because these products may not be fed to animals. The Ad-hoc

monitoringplan still applies, because the sector has focused on sustainability here.

Measured values of Aflatoxin B1 in Corn and corn

processing products: Only 5 exceedance of the maximum level

HG: Maximum level (20 µg/kg). From value

of 20 µg/kg product is not suitable for the market

Mycotoxins

In second place are the mycotoxins. These health-threatening fungal toxins occur in certain kinds of weather during the

growth and flowering mostly in cereals, or at a later stage during storage. Deoxynivalenol (DON) and Zearalenone (ZEA)

pose a particular risk to sows and piglets, which means that major attention is paid to the potential presence of these

contaminants in the feed for this livestock. In addition, numerous raw materials are tested for the mycotoxins Aflatoxin B1

and Ochratoxin (OTA).

Dioxins

A special element of QS feed monitoring is “positive release sampling”. Some production processes are considered parti-

cularly critical. This is why certain feed material and compound feed products have to undergo lot-based positive release

sampling before being brought into circulation – resulting in a higher number of tests for dioxins and dioxin-like PCBs. Re-

lease sampling is necessary for, among other products, refining fatty acids, salts of fatty acids and raw coconut oil as well

as mixed fats and oils processed using fatty acids and mixed fatty acids.

■