Monitoring-

Report Feed 2014

SALMONELLA: MONITORING IN

THE INTERESTS OF CONSUMER

PROTECTION

THE 4 MOST FREQUENT

CONTAMINANTS IN

AGRICULTURE

Salmonella are considered to be the frequent cause of serious gas-

trointestinal illness in humans. A high level of food safety is there-

fore important in order to minimise and wherever possible prevent

the spread of salmonella through slaughtering pigs and poultry. This

is why there are strict hygiene requirements for livestock farmers

stipulated by the legislator and QS. These regulations concern,

among other things, the storage and handling of feed: storage in

closed rooms as well as regular cleaning and disinfection of these

rooms, silos and containers in which feed is stored are a “must” for

farmers and agricultural businesses.

In addition, all poultry and pig farmers should always consider feed

when identifying potential entry pathways for salmonella. To support

them in this process, feed products are subjected to specific tests

for salmonella as part of QS monitoring. This enables farmers to

identify potential risk herds for salmonella contamination at an early

stage and to take appropriate action. This protects the entire value

added chain – from farmer to consumer – by preventing the spread

of contamination. It is worth mentioning that almost 50,000 tests

for salmonella have been carried out to date, and that only 54 sam-

ples were positive – equivalent to just 0.1%. 14 of these samples

came from agricultural businesses.

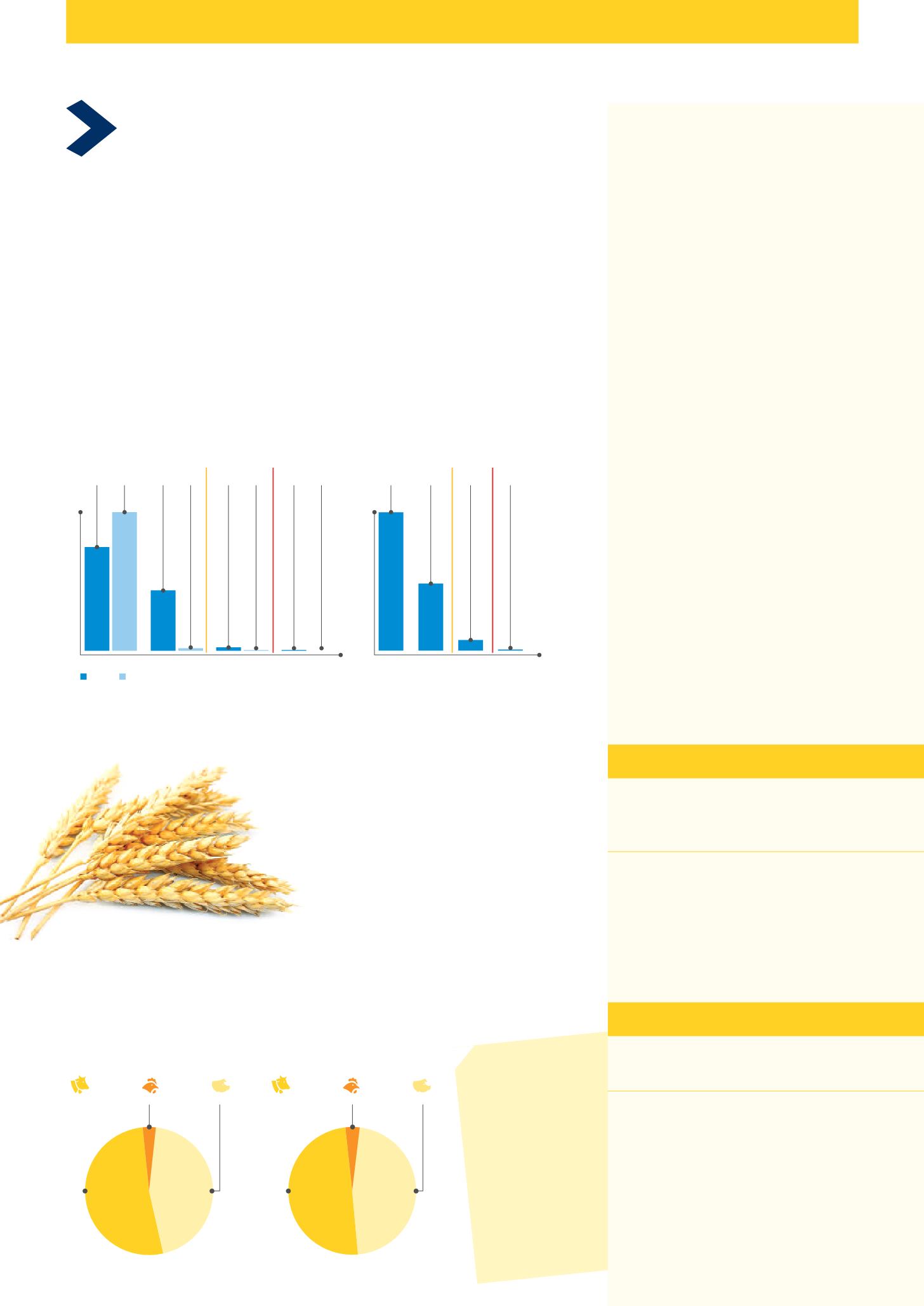

Although DON and ZEA, two mycotoxins that can directly impact

animal health, were frequently detected, it was rare for the values

to exceed admissible limits: out of more than 11,000 tests in total,

levels exceeding the EU reference values were found in only 21

cases.

Antibiotically active substances are among the most frequently in-

vestigated parameters in agriculture - because if they are detected

in a sample, then the product in question must be removed from

the market. Fortunately, this was only the case in 36 out of 3,154

tests, however.

Parameter

Total

tests

Positive

findings

Type of

business

Antibiotically

active substances 3,154 36 15 cattle farming

21 pig farming

Salmonella 7,194 14 3 cattle farming

11 pig farming

Antibiotically active substances and salmonella

Special effect:

acid as preservative

Parameter

Value

measured

DON 6,332 2,872 17 17 pig farming

ZEA 4,966 2,370 4 3 cattle farming

1 pig farming

DON and ZEA

Type of

business

Value excee-

ding limit

Total

tests

918

687

17

400

1

23

0 1

Measured

value

Number analysis

0-0.25 ng/kg

>0.25-0.5 ng/kg

>0.5-0.75 ng/kg

>0.75 ng/kg

Dioxin dl PCB

130

63

10

1

AGW

4 ng/kg

HG

5 ng/kg

>5 ng/kg

>4-5 ng/kg

>2-4 ng/kg

>0-2 ng/kg

AGW

0.5 ng/kg

HG

0.75 ng/kg

A sample tests positive for

antibiotically active substan-

ces although the sample

does not actually contain

any such substances. How

can this happen? Feed like

silage, in which acid is used

as a preservative, can sup-

ply a “false positive” result.

This is why particular atten-

tion should be paid to the

type of feed used for tes-

ting.

FEED MONITORING

ON FARMS

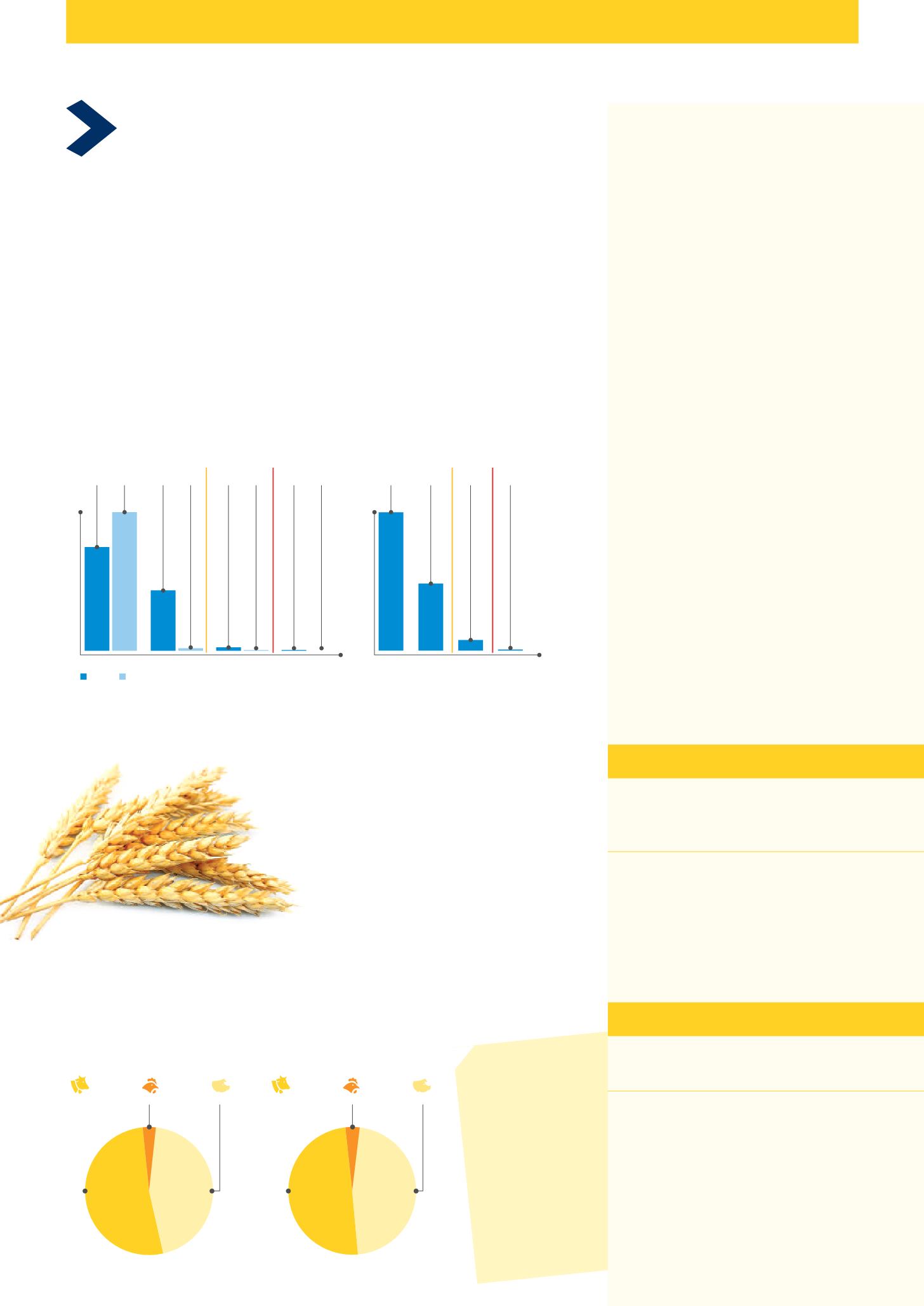

There are just under 50,000 livestock farmers in the QS scheme, who produce their own feed. These “on-farm mixers” ac-

count for roughly one in four of the tests carried out within the framework of feed monitoring. Sampling on the farms is

organised via the coordinators, generally during the independent inspection by the auditor. In total, just under 40,000

tests have been carried out to date, chiefly on cattle and pig farms. The poultry farmers generally use purchased ready

feed for poultry fattening and therefore participate only seldom in the agricultural feed monitoring process.

■

1,439

17,859

20,662

3.8

46.5

49.7

Sampling at agricultural businesses: cattle farmers lead the way

Distribution of samples in %

No. of analysis by type of business

Analysis results of Dioxins and

dl-PCB in oils and fats

Analysis results of Dioxins in fish oil

AGW: Intervention level (0.5 ng/kg). From value of 0.5 ng/kg

company must search for the cause and initiate measures.

HG (only Dioxines): Maximum level. From value of 0.75 ng/kg

product is not suitable for the market

AGW: Intervention level (4 ng/kg). From value of 4 ng/kg

company must search for the cause and initiate measures..

HG: Maximum level (5 ng/kg). From value of 0.75 ng/ kg

product is not suitable for the market

QS RESPONDS SUCCESSFULLY WITH TIGHTENED CONTROL PLANS FOR FATS AND OILS

An incident with far-reaching consequences shook the sector at the beginning of 2011. Some feeds with sometimes high

dioxin concentrations found their way into the marketplace after technical fatty acids had been mixed with fatty acids for

feeding purposes. Consequently, a large number of businesses had to be suspended. QS responded immediately by tighte-

ning its control plans for products containing oils and fats from particularly risky processes with the so-called release in-

spection. Ever since, traders and producers must subject their final products batch by batch to a release inspection prior

to marketing, which also means 100% monitoring. A glance at the results of the current 2,624 analyses shows that thanks

to the strict intervention of QS, the scheme participants now have the situation under control. Accordingly, the legally

prescribed maximum dioxin level was only exceeded in two instances. Although it was above the action threshold in 33

instances, it was still below the maximum level. A similar pattern was seen with dioxin-like PCB where the action threshold

was exceeded in one instance. Even though the numerous tests did not produce any alarming results, they show that

dioxin and PCB still have to be monitored. A reading was determined with 86 % of the samples examined. Dioxin was de-

tected in 817 samples and dioxin-like PCB in 918 – albeit in small quantities. 480 analyses produced results close to the

action threshold, which is almost 20 % of all tests. Conclusion: there is still good reason for diligence, because dioxins

and PCB remain a risk.

■

FLAWLESS RAW MATERIALS

While only few tests showed levels exceeding limit values for unde-

sirable substances, no such levels at all were found for other sub-

stances, such as heavy metals and dioxins. The satisfying results of

feed monitoring are also due to the fact that the farmers handle

feed with extreme care and receive flawless raw materials from the

feed producers. By controlling the raw materials that leave their pre-

mises, the producers play a key role in ensuring safe feed on the

farm.

■

Dioxin incident in 2011 has a lasting

effect on the industry