Introduction of mandatory animal health counselling for conspicuous pig farms in the QS scheme

On 1 November 2024, QS introduced mandatory animal health advice for pig fattening farms whose diagnostic data document abnormalities in animal health over a longer period of time. The farms concerned are selected in stages: Firstly, QS assesses the companies based on the visible slaughter findings over a period of at least six months. Companies with conspicuous results are audited in the next step and only if the negative impression from the findings data is confirmed in this animal health audit must the company seek advice from trained experts. Consultants, livestock owners and the attending veterinarian work together to develop practical solutions to improve individual weaknesses in animal health. The aim of animal health counselling in the QS scheme is to sustainably improve animal health and promote animal welfare.

QS-Soyplus – New standard for more sustainably produced animal feed

As a cross-industry standard setter, QS has developed the QS-Sojaplus standard together with representatives of the entire meat-producing value chain. Since 1 January 2024, the standard has been mandatory for all feed producers and traders who process or trade soya products in the QS scheme. The industry solution applies to all animals and feed from Germany and abroad if they are marketed via the QS scheme. As QS works closely with recognised international standard setters for the QS-Sojaplus standard and has developed mutual recognition agreements, distortions of competition are specifically avoided.

QS introduces new company logo

Since April 2023, QS has summarised all business activities and their communication under a new company logo. The new company logo will be used exclusively by QS employees for correspondence with scheme participants, service providers, media representatives, interest groups and cooperation partners and will also be used by QS for marketing campaigns and for dialogue with consumers. The blue QS certification mark continues to be used as usual to label meat and sausage products, ham and fruit, vegetables and potatoes that are produced and marketed in compliance with the binding quality requirements.

QS programme for pet food production starts

Since March 2023, QS has also been offering a programme for quality and process assurance in the production of dog and cat food for companies in the pet food industry. In cooperation with representatives of the pet food industry, QS has developed a programme for cross-stage quality assurance that takes into account the entire value chain of pet food production. In future, the relevant QS requirements will form the basis for labelling pet food with the product seal of the Animal Welfare Initiative (ITW).

Companies keeping fattening cattle participate in QS antibiotics monitoring

Since 1 January 2023, all fattening cattle farms in the QS scheme have also been participating in QS antibiotics monitoring. This will enable livestock farmers and veterinarians to better evaluate the use of antibiotics on the farm, take countermeasures more quickly if action is required and thus further optimise the use of antibiotics.

QS-Akademie is launched

In mid-May 2020, the QS Academy, QS' knowledge and training portal for fresh food, was launched. With the new portal, QS responds to the increasing demand for further education and training in agriculture and the food industry. With a broad portfolio of workshops, attendance training, web-seminars and e-learning offers, the academy is aimed at all those who come into contact with the topic of quality assurance in their everyday professional life: From the person responsible for quality management in the company, to the sampler and technical adviser, to auditors, laboratory staff and specialist salespeople in the food retail.

QS raises new indices on biosecurity and livestock farming

Since November 2019, QS has been providing its scheme participants from the livestock industry with two new indices. They are determined from the results of the audits. Using the biosecurity index (BSI) and the livestock farming index (LFI), livestock owners can see at a glance where their farm stands in terms of the relevant criteria of biosecurity and livestock farming and in which areas improvement measures are useful.

"ASP-Risikoampel": Evaluation tool for disease pre-vention co-developed by QS goes online

In mid-2019, the University of Vechta presented its ASP risk traffic light developed together with the Friedrich-Loeffler-Institut (FLI) and QS. The online tool, which was developed as part of a research project co-financed by the QS Science Fund, gives pig farmers the opportunity to have the operational biosecurity of their farm evaluated anonymously and free of charge, thus making an important contribution to the prevention of African swine fever

QS-GAP standard: QS achieves Gold status for fruit and vegetable production

In 2018, the Sustainable Agriculture Initiative Platform (SAI Platform), one of the leading initiatives for sustainable agriculture, carried out a review of the QS-GAP standard, whose requirements also apply to QS certified fruit and vegetable producers. The review also included a comparison with the requirements of the Farm Sustainability Assessment 2.0 (FSA) benchmarking tool, which is a recognized reference for promoting sustainable agriculture. The result is impressive: With its Gold status, the QS-GAP standard achieved the highest FSA rating for sustainability.

Range of products for fresh fruit and vegetables with QS certifica-tion extended in the food retail

Since September 2018 the trading company LIDL has been labelling fresh fruit and vegetables with the QS certification mark. By displaying the certification mark on the product packaging, LIDL gives its customers a clear signal for buying safe food from reliable producers and suppliers and underlines that freshness and quality of fruit and vegetables are the company's top priority.

New stage Preparation/Processing implemented in the supply chain fruit, vegetables, potatoes

Since 1 January 2017, processing processes can be certified in addition to the preparation of fruit, vegetables and potatoes. The new stage Preparation/Processing is interesting for companies conducting processing operations (e.g. freezing and heating processes) as well as for businesses that produce fresh-cut products or prepare germbuds and sprouts. By participating, a clear signal for practice-oriented requirements is sent. Additionally, businesses show that the compliance with hygiene rules and microbiological standards have the highest priority.

New stage Preparation/Processing implemented in the supply chain fruit, vegetables, potatoes

Since 1 January 2017, processing processes can be certified in addition to the preparation of fruit, vegetables and potatoes. The new stage Preparation/Processing is interesting for companies conducting processing operations (e.g. freezing and heating processes) as well as for businesses that produce fresh-cut products or prepare germbuds and sprouts. By participating, a clear signal for practice-oriented requirements is sent. Additionally, businesses show that the compliance with hygiene rules and microbiological standards have the highest priority.

Coordination platform adopt key issue paper for renouncing piglet castration without anesthesia

According to new legal regulations, from 1 January 2019 piglets may no longer be castrated in Germany without anaesthesia. On 18 April 2016 the participants in the QS Coordination Platform renouncing piglet castration without anaesthesia

speak in favour of a joint and active approach in order to achieve a timely and orderly way of abandoning surgical castration of piglets without anaesthesia that is both justifiable from an animal welfare point of view and economically viable for all concerned.

Regionalfenster: QS audits regarding traceability recognised

Since 1 April 2015 livestock farmers and producers of fruit, vegetables and potatoes of the QS scheme are able to participate in the programme Regionalfester

without an additional audit. The agreement between QS and Regionalfenster e.V. contribute to new sales opportunities for QS scheme participants without generating additional costs that come along with duplicate auditing.

QS for logistics service providers becomes obligatory

Since 1 January 2015, logistics service providers who regularly transport fresh fruit and vegetables for QS scheme participants have to be registered in the QS database for the production scope logistic. The requirements focus on hygiene and traceability during transport and pave the way for practice-oriented quality assurance. QS has already been offering the logistic standard since 1 January 2013.

Integration of breeding farms and hatcheries in the QS scheme

In mid-2014 the control network of the QS scheme becomes even more stringent: Since 1 July 2014 broiler and turkey producers are only allowed to breed chicks from QS certified hatcheries. In order to produce QS chicks, hatcheries have to source their hatching eggs from QS certified breeding farms.

Ten years QS quality assurance for fruit, vegetables and potatoes

In February 2014, the QS Fachgesellschaft Obst, Gemüse, Kartoffeln celebrates its 10th anniversary with the sector on the FRUIT LOGISTICA in Berlin, where its starting shot was given in 2004. With the QS scheme for fruit, vegetables and potatoes, the economy has gone a consistent path towards a preventive consumer protection. Within a decade, not only a quality scheme for fresh fruit and vegetables has been established, but also a number of further quality assurance measures and a comprehensive residue monitoring have been launched.

QS scheme integrity system extended by unannounced audits

On 1 January 2013 the QS scheme integrity system is extended by unannounced audits. Companies of the supply chain meat and meat products have the choice between unannounced regular audits and unannounced spot audits. By implementing the unannounced audits, it is ensured that the requirements are also complied with consistently between scheduled regular audits.

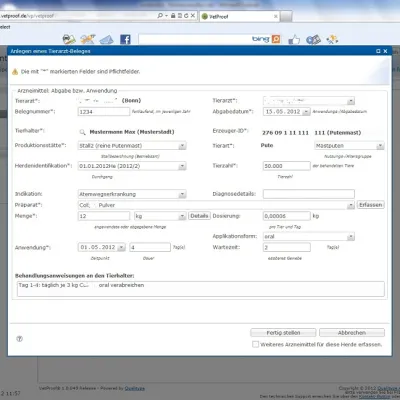

Start of antibiotic monitoring for pig production farms

After implementing the comprehensive collection of antibiotic prescriptions for poultry in April 2012, the QS Qualität und Sicherheit GmbH integrated the antibiotic data for all QS certified pig production farms in its database on 1 September 2012. With this another important step towards the collection of antibiotic prescriptions in livestock farming is taken.

Antibiotics database is online

On 2 April 2012 the QS Qualität und Sicherheit GmbH started its data collection for the antibiotic monitoring - initially for broiler and turkey production. Within only three months, the basics of the programme are developed, adopted and implemented and a database application is programmed.

Ten years of QS

Founded on 13th October 2001, the QS scheme celebrates its tenth anniversary in October 2011.This will be celebrated at the place of foundation on the Anuga. Markus Mosa, chairman of the shareholders meeting on the anniversary: Since the 13th October 2001, quality assurance within food industry has changed for the better. The foundation of QS sets a clear signal of agriculture, industry and food retail to become active together. Within the last ten years a comprehensive inspection system for fresh meat and sausage products as well as or fruit and vegetables emerged, which enjoys huge recognition among experts.

QS communicates in social networks

Since Mai 2011 QS is active on Twitter. Short messages with a maximum length of 140 characters (so called tweets

) offer information for interested experts. On the occasion of its tenth anniversary QS will take the next step into the interactive internet and start its own blog.

First consequences of the dioxin incident

As a consequence of the dioxin incident at the beginning of 2011, QS tightens the requirements in the feed sector. The QS scheme, as a dynamic organisation, reacts quickly and concertedly in several adjustment steps: by 1 March and 1 July tightened requirements were adopted, further adaptations shall follow with the revision which will come into effect on 1 January 2012. The adopted measures will further increase feed security and assure that products can be traced back even faster.

Launch of consumer webiste

Until 2009, the CMA (German marketing agency for agricultural products) was responsible for advertising and public relations on the subject of the QS certification mark. With the liquidation of the CMA and its departure as shareholder at the beginning of 2009, a gap appeared in terms of consumer communication. This gap could be filled to some extent with the new consumer portal www.qs-pruefsystem.de. Here, consumers get useful information on the QS certification mark, quality assurance in the different stages of food production and product knowledge – for the proper handling of products they bought.

Federal politics relies on cross-stage quality assurance

In their coalition statement, the newly elected government consisting of CDU and FDP promotes the expansion of privately organized cross-stage quality assurance schemes and their interlocking with the state food control

. It thereby gives a boost to the cross-stage system which forms the basis for the work of QS.

Coordination platform on piglet castration takes up work

Expert workshop confirms great need of action and research: The question of how to completely renounce piglet castration in the long run was discussed by more than 130 experts and speakers from science, industry and animal welfare organisations on the occasion of an expert workshop held by QS and Deutschen Gesellschaft für Züchtungskunde e.V. (German Society for Animal Production) on 9th March 2009 in Kassel. The workshop was the debut event of the QS Coordination platform Renouncing piglet castration

. Although the common objective, the complete elimination of piglet castration, is clearly defined, it becomes obvious that clarification is still needed when it comes to practical implementation.

100.000th scheme participant

With handing out the QS certificate to the pig producer Engelbert van Bevern in Muenster on 5th September 2007, QS welcomes the 100.000th scheme participant in the supply chain meat and meat products.

Pictured from left to right: Dr. Alfons Rensing, managing director of the certification body ACG Agrar-Control GmbH, Mr. and Mrs. van Bevern, Franz-Josef Möllers, president of Westphalia-Lippe Agricultural Association and chairman of the advisory board for beef, veal and pork and Dr. Hermann-Josef Nienhoff, managing director of QS.

First meat with QS certification mark in self-service counters of the food discount

After the service counter, meat labelled with the QS certification mark also conquers self-service counters and can be purchased in the food discount for the first time in February 2006. This marks an important step for scheme participants as it shows that retail puts increasingly trust in quality assurance with the QS certification mark.

Change of QS certification mark

The QS certification mark got a makeover. The result, the stage symbol

which is still used today, is presented in October 2005: the arrow with five steps represents the cross-stage inspection of foodstuffs from farm to shop

.

The picture illustrates the first presentation of the new certification mark by Professor Stefan Feuerstein (right), chairman of the QS shareholders meeting and board member of the Metro AG, who unveils the new certification mark together with Franz-Josef Möllers (left), president of Westphalia-Lippe Agricultural Association and chairman of the advisory board for beef, veal and pork.

Start of residue monitoring for fruit and vegetables

With introducing the residue monitoring for fruit, vegetables and potatoes in March 2005, QS establishes an effective system of regular product controls on all stages of the supply chain. The efficiency of this instrument is shown by the considerably lower residue levels in various products. Since August 2006 QS also evaluates the work of laboratories: only those who successfully pass a laboratory performance assessments once a year are allowed to perform analyses in the QS scheme.

EU regulation 178/2002 comes into force

In January 2005 the EU regulation 178/2002 comes into force. The demands set out with regard to self-assessment and traceability are key requirements in the QS scheme. Economic operators are responsible for food safety and use the QS scheme for consistent implementation and documentation.

Europa und Internationales

Because of its steady growth, the QS scheme becomes increasingly important for quality assurance even on international level. In order to allow an unimpeded flow of goods with comparable quality assurance, QS promotes transnational cooperation on various levels. Important milestones are:

- In October 2004 the European Meat Alliance (EMA) is founded to allow a cross-scheme goods traffic by means of mutual recognitions:

- Since January 2005 it is possible to conduct combined IFS/QS audits. This means, that the International Food Standard (IFS) and QS requirements for food retail and wholesale can be assessed together in one audit by independent certification bodies.

- From January to March 2005, mutual recognitions with several standards in Europe can be concluded: with the QSG standard in Denmark, the Certus and the GMP standards in Belgium as well as with the standards IKB and GMP+ in the Netherlands.

- Since September 2006, the QS-GAP standard allows mutual recognition between QS and GlobalG.A.P. (at that time still EUREPGAP). From then on, producers of fruit, vegetables and potatoes may deliver their goods into the respective other scheme.

- QS currently possesses mutual recognitions with a total of 13 standard owners.

Foundation of QS Fachgesellschaft Geflügel GmbH

In order to provide a better response to the special demands of the poultry industry, the QS Fachgesellschaft Geflügel GmbH is founded in June 2004. As previously in the red meat sector and for fruit and vegetables, the QS scheme establishes itself quickly.

Foundation of QS Fachgesellschaft Obst-Gemüse-Kartoffeln GmbH

Having successfully established the QS scheme in meat sector, there are growing calls for a similar quality assurance for fruit and vegetables – the QS Fachgesellschaft Obst-Gemüse-Kartoffeln GmbH is founded in February 2004. From then on producers, wholesalers and food retailers in the fruit and vegetable sector can decide for quality assurance with the QS certification mark, too.

Incident and crisis management is set up

To further protect scheme participants and, at the end of the chain, consumers, QS set up an incident and crisis management. It obliges all scheme participants to report every incident directly to QS that is considered critical. QS thus has the possibility to quickly respond to incidents, to support the business concerned in problem solving and to ensure food safety – also by blocking a scheme participant, if necessary.

Start of the QS salmonella programme

Animal welfare and hygiene are important issues within the QS scheme. In order to effectively address the risk of salmonella, pig production businesses in the QS scheme are obliged to participate in the close-knit monitoring of salmonella since April 2003. A measure that has proven successful: the number of salmonella infections in humans and animals could be reduced considerably since than. Almost 10 million samples have been taken, analysed and recorded within the database of the QS scheme since the introduction of the salmonella programme.

First products with QS certification mark in food retail

From farm to shop

: In September 2002, less than one year after the foundation of the QS scheme, the first meat products labelled with the QS certification mark are commercially available. Nowadays, more than 23.000 food retail branches sell products labelled with the QS certification mark.

First scheme agreement

Just a few months after the foundation of QS at the end of 2001, the first agreement with a scheme participant is signed in February 2002. Westfleisch e. G. is the first contractual partner of QS. The first QS audit is carried out in a pig production business. Having been audited succesfully, this business participates in the QS scheme via the coordinator Westfleisch. It was was followed by around 93.000 further agricultural businesses that are taking part in the QS scheme via a coordinator today.

Foundation of QS Qualität und Sicherheit GmbH

On 13 October 2001, representatives from all of meat production stages meet to sign the shareholders agreement of QS Qualität und Sicherheit GmbH.

Pictured left to right: Dr. Rolf Meyer, Deutscher Raiffeisenverband e. V. (German Raiffeisen Association), Thomas Vogelsang, Bundesverband der Deutschen Fleischwarenindustrie e.V. (Federal Association of the German Meat Industry), Peter Zühlsdorff, chairman of the shareholders meeting and the Handelsvereinigung für Marktwirtschaft (Action Group for the Market Economy in German Retailing), Dr. Klaus-Dieter Baehrfeld, Verband der Fleischwirtschaft e.V. (Association of the Meat Industry), sitting in front on the left side Jörn Johann Dwehus, Centrale Marketing-Gesellschaft der deutschen Agrarwirtschaft mbH (German marketing agency for agricultural products) und Dr. Helmut Born, Deutscher Bauernverband e. V. (German Farmers` Federation).